What is high frequency material?

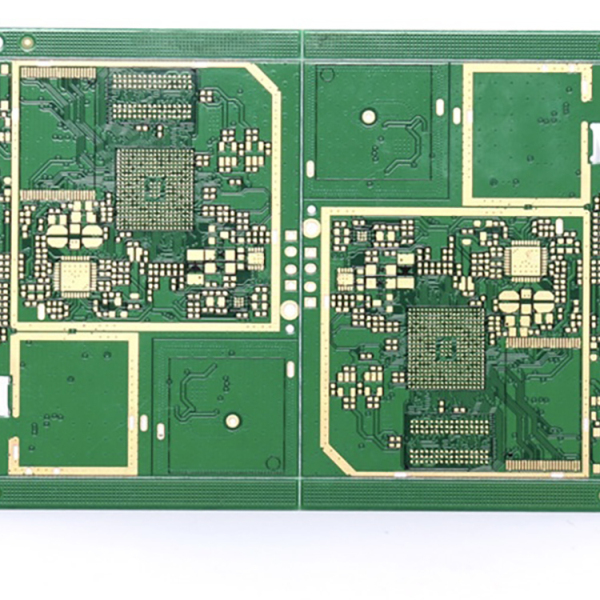

High frequency board refers to a special circuit board with high electromagnetic frequency, which is used for PCB (Microwave radio frequency board) in high frequency (frequency greater than 300MHZ or wavelength less than 1 meter) and microwave (frequency greater than 3GHZ or wavelength less than 0.1 meter). It is a circuit board produced on a microwave substrate copper clad board using part of the process of the ordinary rigid printed circuits manufacturing method or using a special processing method. Generally speaking, a high-frequency board can be defined as a circuit board with a frequency above 1GHz. For example: high frequency mixing pressure plate.

With the rapid development of science and technology, more and more equipment is designed for applications in the microwave frequency band (>1GHZ) or even in the millimeter wave field (30GHZ). This also means that the frequency is getting higher and higher, and the circuit board is The requirements for materials are getting higher and higher. For example, the substrate material needs to have excellent electrical properties, good chemical stability, and the loss on the substrate with the increase of the power signal frequency is very small, so the importance of the high-frequency board is highlighted.

PCB high frequency board classification

1, the end ceramic filled with thermosetting material

processing methods:

The processing process is similar to epoxy resin/glass woven cloth (FR4), except that the sheet is relatively brittle and easy to break. When drilling and gongs, the life of the drill and gong knife will be reduced by 20%.

2, PTFE (polytetrafluoroethylene) material

processing methods:

1. Cutting material: The protective film must be kept for cutting material to prevent scratches and creasing

2. Drilling:

2.1 Use a brand new drill bit (standard 130), one by one is the best, the pressure of the presser foot is 40psi

2.2 aluminum sheet is used as the cover plate, and then 1mm melamine backing plate is used to tighten the PTFE plate

2.3 After drilling, use an air gun to blow out the dust in the hole

2.4 Use the most stable drilling rig and drilling parameters (basically the smaller the hole, the faster the drilling speed, the smaller the Chip load, the smaller the return speed)

3. Hole treatment

Plasma treatment or sodium naphthalene activation treatment is conducive to hole metallization

4.PTH Immersion Copper (for example: 6 layer Rigid-flex Immersion Gold PCB)

After 4.1 micro-etching (with 20 micro-inch control of the micro-etching rate), pull the plate into the plate from the de-oil cylinder in the PTH

4.2 If necessary, pass the second PTH, just from the estimate? The cylinder starts to enter the plate

5. Solder mask

5.1 Pre-treatment: Use acidic plate washing instead of mechanical grinding plate

5.2 Pre-treatment and post-baking plate (90℃, 30min), brush with green oil to cure

5.3 Three-stage baking: one section of 80℃, 100℃, 150℃, each for 30 minutes (if you find that the substrate surface is oily, you can rework: wash off the green oil and reactivate it)

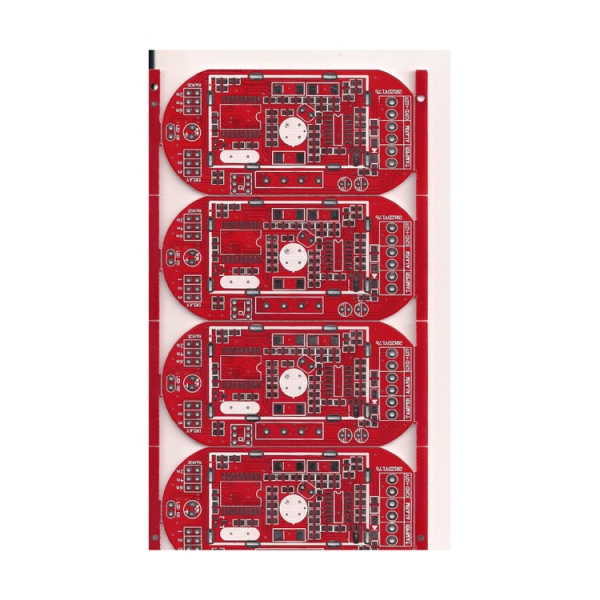

6. Gong board

Lay white paper on the circuit surface of the PTFE board, and clamp it up and down with the FR-4 substrate board or phenolic base plate with a thickness of 1.0MM etched to remove the copper: as shown in the figure:

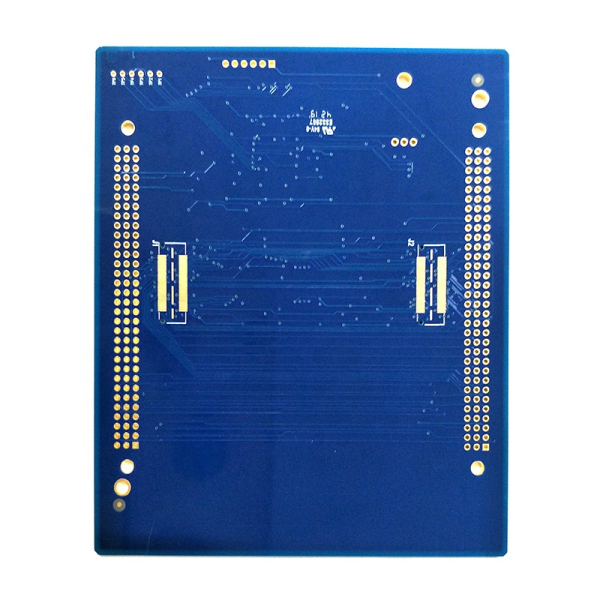

high frequency and high speed sheet material

When selecting the substrate used for the PCB used in the high-frequency circuit, special consideration should be given to the change characteristics of the material DK under different frequencies. As for the requirements for high-speed signal transmission or characteristic impedance control, the focus is on DF and its performance under conditions such as frequency, temperature and humidity.

Under the condition of frequency change, the general type substrate material shows the law of large changes in DK and DF values. Especially in the frequency from 1 MHz to 1 GHz, their DK and DF values change more obviously. For example, a general epoxy resin-glass fiber cloth-based substrate material (general FR-4) has a DK value of 4.7 at a frequency of 1 MHz, and a DK value of 4.19 at a frequency of 1 GHz. Above 1GHz, the change trend of its DK value is gentle. The trend of its change is that as the frequency increases, it becomes smaller (but the change is not large). For example, at l0GHz, the DK value of FR-4 is 4.15. The substrate material with high-speed and high-frequency characteristics changes in frequency. In the case of, the change of DK value is small, and the change of DK is mostly kept in the range of 0.02 under the changing frequency from 1MHz to 1GHz. Its DK value tends to decrease slightly under different frequency conditions from low to high.

The dielectric loss factor (DF) of the general substrate material is affected by frequency changes (especially changes in the high frequency range) and the change in DF value is greater than that of DK. The law of its change tends to increase. Therefore, when evaluating the high-frequency characteristics of a substrate material, the focus of its investigation is the change of its DF value. For substrate materials with high-speed and high-frequency characteristics, in terms of changing characteristics at high frequencies, there are two distinct types of general substrate materials: one is that with the change of frequency, its (DF) value changes very little . There is another type that is similar to the general substrate material in the range of change, but its own (DF) value is lower.

How to choose high-frequency and high-speed plates

The choice of PCB board must strike a balance between meeting design requirements, mass production, and cost. Simply put, design requirements include electrical and structural reliability. Usually this board problem is more important when designing very high-speed PCB boards (frequency greater than GHz). For example, the commonly used FR-4 material now has a large dielectric loss Df (Dielectricloss) at a frequency of several GHz, which may not be applicable.

For example, a 10Gb/S high-speed digital signal is a square wave, which can be seen as a superposition of sine wave signals of different frequencies. Therefore 10Gb/S includes many different frequency signals: 5Ghz fundamental wave signal, 3rd order 15GHz, 5th order 25GHz, 7th order 35GHz signal and so on. Maintain the integrity of the digital signal and the steepness of the upper and lower edges are the same as the low-loss and low-distortion transmission of radio frequency microwave (the high-frequency harmonic part of the digital signal reaches the microwave frequency band). Therefore, in many aspects, the selection of high-speed digital circuit PCB materials is similar to that of RF microwave circuits.

In actual engineering operations, the selection of high-frequency plates seems simple, but there are still many factors that need to be considered. Through the introduction of this article, as a PCB design engineer or high-speed project leader, you have a certain understanding of the characteristics and selection of plates. . Understand the electrical properties, thermal properties, and reliability of sheets. And rational use of stacking, design a product with high reliability and good processability, the consideration of various factors is optimized.

The following will introduce separately, the main considerations for choosing the right sheet:

1. Manufacturability:

such as the performance of multiple pressing, temperature performance, etc., resistance to CAF/heat resistance, mechanical toughness (adhesive) (good reliability), fire rating;

2. Various properties matching the product (electrical, performance stability, etc.):

Low loss, stable Dk/Df parameters, low dispersion, small variation coefficient with frequency and environment, small tolerance of material thickness and glue content (good impedance control), if the trace is long, consider low roughness copper foil. In addition, the design of high-speed circuits requires simulation in the early stage, and the simulation results are the reference standard for the design. "Xingsen Technology-Agilent (High-speed/RF) Joint Laboratory" solved the performance problem of inconsistent simulation results and tests. It has done a lot of simulation and actual test closed-loop verification, and can achieve the same simulation and actual measurement through a unique method.

What are the PCB high-frequency plates? PCB high-frequency plate classification

3. Timely availability of materials:

Many high-frequency plates have a very long procurement cycle, even 2-3 months; in addition to the conventional high-frequency plate RO4350 in stock, many high-frequency plates need to be provided by customers. Therefore, high-frequency plates need to communicate with the manufacturer in advance and prepare the materials as soon as possible;

4. Cost factor Cost:

It depends on the price sensitivity of the product, whether it is a consumer product, or a communication, medical, industrial, or military application;

5. Applicability of laws and regulations, etc.:

must be integrated with the environmental protection regulations of different countries to meet the requirements of RoHS and halogen-free.

Among the above factors, the operating speed of high-speed digital circuits is the main factor considered in PCB selection. The higher the circuit speed, the smaller the selected PCBDf value. Circuit boards with medium and low loss will be suitable for 10Gb/s digital circuits; boards with lower loss are suitable for 25Gb/s digital circuits; boards with ultra-low loss will be suitable for faster high-speed digital circuits, and the rate can be 50Gb /s or higher.

From the material Df:

Df between 0.01~0.005 circuit board suitable for upper limit of 10Gb/S digital circuit;

Df is between 0.005~0.003, the suitable upper limit of circuit board is 25Gb/S digital circuit;

The circuit board with Df not exceeding 0.0015 is suitable for 50Gb/S or even higher-speed digital circuits.

The commonly used high-speed plates are:

1) Rogers Rogers: RO4003, RO3003, RO4350, RO5880, etc.

2), Tai Yao TUC: Tuc862, 872SLK, 883, 933, etc.

3), Panasonic: Megtron4, Megtron6, etc.

4), Isola: FR408HR, IS620, IS680, etc.

5), Nelco: N4000-13, N4000-13EPSI, etc.

6), Dongguan Shengyi, Taizhou Wangling, Taixing Microwave, etc.

The above summarized how to select high-speed plates and design considerations. In practice, the application needs to be analyzed based on specific cases.

Contact us if you need more details on Rogers Material Circuit Board. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High-tech Pcb Board、High Frequency Pcb Board. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : High Frequency Board > Flame Resistant PCB